YB_T 5267-2013莫来石/Mullite

莫来石

1 范围

本标准规定了莫来石的术语和定义、分类与牌号、技术要求、试验方法、验收规则和包装、标志、运输、贮存及质量证明书。

本标准适用于氧化铝、矾土、硅石、黏土为主要原料,采用烧结或电熔工艺所生产的主晶相为莫来石、不含石英相的耐火原料。

2规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅所注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件

GB/T 2999 耐火材料颗粒体积密度试验方法

GB/T 6900 铝硅系耐火材料化学分析方法

GB/T 7322耐火材料耐火度试验方法

GB/T 17617 耐火原料与不定形耐火材料 取样

GB/T 21114 耐火材料 X射线荧光光谱化学分析熔铸玻璃片法

YB/T 172 硅砖定量相分析 X射线衍射法

YB/T 5142 冶金矿产品包装、标志、运输、贮存和质量证明书

YS/T 89-1995(2005) 煅烧α型氧化铝

3术语和定义

下列术语和定义适用于本文件。

3.1

烧结莫来石 sintered mullite

采用烧结工艺合成的莫来石。

3.2

电熔莫来石 fused mullite

采用电熔工艺合成的莫来石。

4 分类与牌号

4.1 分类

4.1.1 按生产工艺分为烧结和电熔两类。

4.1.2 产品按氧化铝标称含量分为SM75、SM70-1、SM70-2、SM60-1、SM60-2、FM75及FM70 共7个牌号。

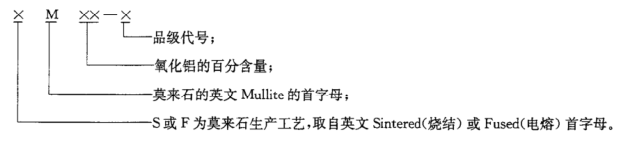

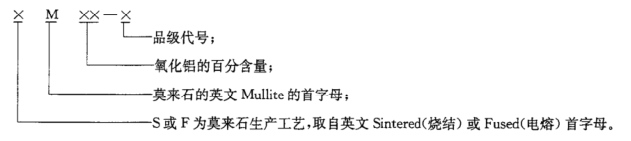

4.2 牌号

莫来石牌号由字母和数字构成,其表示如下所示。

示例 1:SM60-1 烧结莫来石,氧化铝含量为60%的1级品;

示例 2:FM70 电熔莫来石,氧化铝含量为70%。

5 技术要求

莫来石的理化性能指标应符合表1的规定。

|

表1莫来石理化性能 |

||||||||

|

牌号 |

化学成分(质量分数)/% |

体积密度 g/cm³ |

显气孔率% |

耐火度 CN |

莫来石相含量(质量分数)/% |

|||

|

Al2O3 |

TiO2 |

Fe2O3 |

Na2O+K2O |

|||||

|

SM75 |

73~77 |

≤0.5 |

0.5 |

≤0.2 |

≥2.90 |

≤3 |

180 |

≥90 |

|

SM70-1 |

69~73 |

≤0.5 |

≤0.5 |

≤0.2 |

≥2.85 |

≤3 |

180 |

≥90 |

|

SM70-2 |

67~72 |

≤3.5 |

≤1.5 |

≤0.4 |

≥2.75 |

≤5 |

180 |

≥85 |

|

SM60-1 |

57~62 |

≤0.5 |

≤0.5 |

≤0.5 |

≥2.65 |

≤5 |

180 |

≥80 |

|

SM60-2 |

57~62 |

≤3.0 |

≤1.5 |

≤1.5 |

≥2.65 |

≤5 |

180 |

≥75 |

|

FM75 |

73~77 |

≤0.1 |

≤0.2 |

≤0.2 |

≥2.90 |

≤5 |

180 |

≥90 |

|

FM70 |

69~73 |

≤2.0 |

≤0.6 |

≤0.5 |

≥2.90 |

≤4 |

180 |

≥85 |

|

注1:产品不得检出石英相。 |

||||||||

6 试验方法

6.1 化学成分的测定按 GB/T 6900 或 GB/T 21114 的规定进行。

6.2 体积密度、显气孔率的测定按 GB/T 2999 的规定进行。

6.3耐火度的测定按 GB/T 7322 的规定进行。

6.4石英相含量的测定按 YB/T 172 的规定进行。

6.5 莫来石相含量的测定按照附录 A的规定进行,

7 验收规则

7.1组批莫来石按批检验,每批产品由同一生产条件、同一牌号组成。每一批为一检验单位,每批量不超过100t,或供需双方协商确定。

7.2 抽样和制样

7.2.1 抽样

莫来石的抽样按 GB/T 17617 的规定进行,

7.2.2 制样

抽取的试样应预先破碎成小于10mm的颗粒后再缩分。制备的综合试样重量应不少于10kg。取其中5kg进行理化指标测定,其余5kg留作备份样。

7.3 判定与复验

7.3.1 判定

检验结果应按表1的要求进行判定。

7.3.2 复验

莫来石理化指标检验结果中,如有一项指标不符合要求时,用备份样对不合格项目进行复检,并以复验结果作为该批产品的最终检验结果,

8包装、标志、运输、贮存及质量证明书

8.1 莫来石的包装、标志、运输、贮存及质量证明书按 YB/T 5142 的规定进行。

8.2莫来石的运输工具须清洁,并有防雨、防雪设施。运输过程中严防受潮湿和污染

8.3莫来石必须贮存在不受潮湿的库房内。

Mullite

1 Range

This standard specifies the terms and definitions, classification and grades of mullite, technical requirements, test methods, acceptance rules and packaging, marking, transportation, storage and quality certificates.

This standard applies to alumina, bauxite, silica, clay as the main raw materials, the main crystal phase produced by sintering or electromelting process is mullite, does not contain quartz phase refractory raw materials.

2 Normative reference documents

The following documents are essential for the application of this document. For dated references, only the dated version applies to this document. For undated references, the latest version (including all amendment orders) applies to this document

GB/T 2999 refractory particle bulk density test method

GB/T 6900 aluminum-silicon refractory chemical analysis method

GB/T 7322 refractoriness test method

GB/T 17617 Sampling of refractory raw materials and amorphous refractory materials

GB/T 21114 refractories by X-ray fluorescence spectrochemical analysis of fused cast glass sheets

YB/T 172 silicon brick quantitative phase analysis by X-ray diffraction method

YB/T 5142 Certificate of packaging, marking, transportation, storage and Quality of metallurgical mineral products

YS/T 89-1995(2005) calcined α-type alumina

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Sintered mullite

Mullite synthesized by sintering process.

3.2

Fused mullite

Mullite synthesized by electromelting process.

4 Classification and grade

4.1 Classification

4.1.1 According to the production process, it is divided into sintering and electric melting.

4.1.2 According to the nominal content of alumina, the products are divided into seven grades: SM75, SM70-1, SM70-2, SM60-1, SM60-2, FM75 and FM70.

4.2 Brand

The Mullite number is composed of letters and numbers, which are represented as follows.

Example 1:SM60-1 sintered mullite, Grade 1 with 60% alumina content;

Example 2:FM70 fused mullite with 70% alumina content.

5 Technical Requirements

The physical and chemical properties of mullite should conform to the provisions of Table 1.

|

Table 1 Physical and chemical properties of mullite |

||||||||

|

Brand |

Chemical composition(Mass fraction)/% |

Bulk density g/cm³ |

Apparent porosity% |

Refractoriness CN |

Mullite phase content (mass fraction)/% |

|||

|

Al2O3 |

TiO2 |

Fe2O3 |

Na2O+K2O |

|||||

|

SM75 |

73~77 |

≤0.5 |

0.5 |

≤0.2 |

≥2.90 |

≤3 |

180 |

≥90 |

|

SM70-1 |

69~73 |

≤0.5 |

≤0.5 |

≤0.2 |

≥2.85 |

≤3 |

180 |

≥90 |

|

SM70-2 |

67~72 |

≤3.5 |

≤1.5 |

≤0.4 |

≥2.75 |

≤5 |

180 |

≥85 |

|

SM60-1 |

57~62 |

≤0.5 |

≤0.5 |

≤0.5 |

≥2.65 |

≤5 |

180 |

≥80 |

|

SM60-2 |

57~62 |

≤3.0 |

≤1.5 |

≤1.5 |

≥2.65 |

≤5 |

180 |

≥75 |

|

FM75 |

73~77 |

≤0.1 |

≤0.2 |

≤0.2 |

≥2.90 |

≤5 |

180 |

≥90 |

|

FM70 |

69~73 |

≤2.0 |

≤0.6 |

≤0.5 |

≥2.90 |

≤4 |

180 |

≥85 |

|

Note 1: Quartz phase shall not be detected in the product. Note 2: The detection of mullite phase content is determined by negotiation between the supply and demand parties. |

||||||||

6 Test methods

6.1 Chemical composition shall be determined in accordance with GB/T 6900 or GB/T 21114.

6.2 The measurement of bulk density and apparent porosity shall be carried out according to GB/T 2999.

6.3 Refractories shall be determined according to GB/T 7322.

6.4 The quartz phase content is determined according to YB/T 172.

6.5 Mullite phase content is determined in accordance with Appendix A,

7 Acceptance Rules

7.1 Batches of mullite are inspected according to batch, and each batch of products is composed of the same production conditions and the same brand. Each batch is an inspection unit, each batch does not exceed 100t, or the supply and demand parties to determine through negotiation.

7.2 Sampling and sample preparation

7.2.1 Sampling

Sampling of mullite is carried out according to GB/T 17617,

7.2.2 Sample preparation

The sampled sample should be pre-broken into particles less than 10mm and then shrunk. The weight of the synthesized sample shall not be less than 10kg. 5kg was taken for physical and chemical index determination, and the other 5kg was kept as backup sample.

7.3 Judgment and retest

7.3.1 Decision

The test results shall be judged according to the requirements in Table 1.

7.3.2 Retest

In the test results of physical and chemical indicators of mullite, if one index does not meet the requirements, the backup sample is used to retest the unqualified items, and the retest result is used as the final test result of the batch of products.

8 Packing, marking, transportation, storage and quality certificate

8.1 The packing, marking, transportation, storage and quality certificate of mullite shall be carried out in accordance with YB/T 5142.

8.2 The transport of mullite shall be clean and provided with rain and snow protection facilities. Prevent moisture and contamination during transportation

8.3 Mullite must be stored in a warehouse free from moisture.