JC/T 616-2003 玻璃窑用优质硅砖 High quality silica brick for glass kiln

玻璃窑用优质硅砖

1范围

本标准规定了玻璃窑用优质硅砖的分类、技术要求、试验方法、检验规则及标志、包装、运输、储存和质量证明书的要求。

本标准适用于砌筑玻璃察用机压成型的单重不大于40kg的优质硅砖(以下简称产品)。

2规范性引用文件

下列文件中的条款通过本标准的引用而成为本标准的条款。凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据本标准达成协议的各方研究是否可使用这些文件的最新版本。凡是不注日期的引用文件,其最新版本适用于本标准。

GB/T 29972000致密定形耐火制品显气孔率、吸水率、体积密度和真气孔率试验方法。

GB/T 5071耐火材料真密度试验方法。

GB/T 5072致密定形耐火制品常温耐压强度试验方法。

GB/T 5988致密定形耐火制品重烧线变化试验方法。

YB/T 370–1995耐火制品荷重软化温度试验方法 (非示差一升温法)。

GB/T 6901硅质耐火材料化学分析方法。

GB/T 7320.1耐火制品热膨胀试验方法。

GB/T 7321致密定形耐火制品试验的制样规定。

GB/T 10325-2001定形耐火制品抽样验收规则。

GB/T 10326-2001耐火制品尺寸、外观及断面的检查方法。

GB/T 16546-1996定形耐火制品包装、标志、运输和储存。

YB/T 4017玻璃窑用耐火制品形状尺寸 硅砖。

3 分类、形状及尺寸

3.1 分类产品按其单重分为三个牌号,见表 1

|

表1 产品的分类 |

|

|

牌号 |

单重,kg |

|

XBG-96 |

≤15 |

|

ZBG-96 |

15.1~25 |

|

DBG-96 |

25.1~40 |

注1:牌号中X、2、D分别是指:小、中、大的汉语拼音首字母。B和G是指玻璃窑和硅砖的汉语拼音首字母。

3.2 产品的形状尺寸应符合YB/T4017的规定

4技术要求

4.1产品的理化性能指标应符合表2的规定

|

表2产品的理化性能指标 |

||||||

|

项 目 |

单位 |

指 标 |

||||

|

XBG-96 |

ZBG-96 |

DBG-96 |

||||

|

化学成分 |

SiO2 |

≥ |

% |

96 |

96 |

96 |

|

Fe2O3 |

≤ |

% |

0.8 |

0.8 |

0.8 |

|

|

熔融指数(Al2O3)+2RO2) |

≤ |

% |

0.5 |

0.5 |

0.5 |

|

|

物理性能 |

显气孔率 |

≤ |

% |

21 |

21 |

21 |

|

真密度 |

≤ |

g/cm³ |

2.34 |

2.34 |

2.34 |

|

|

0.2MPa 荷重软化 |

≥ |

℃ |

1680 |

1680 |

1680 |

|

|

常温耐压强度 |

≥ |

MPa |

35 |

30 |

30 |

|

|

重烧线变化(1450℃x2h) |

≤ |

% |

+0.2 |

+0.2 |

+0.2 |

|

|

热膨胀率(0℃~1450℃) |

% |

提供实测数据 |

||||

4.2产品的外观质量、尺寸允许偏差及断面检查应符合表3的规定

4.3手工砖及单重大于 40kg 砖,其技术要求由供需双方商定,

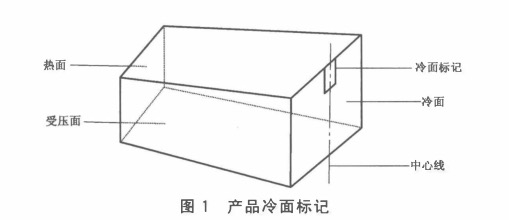

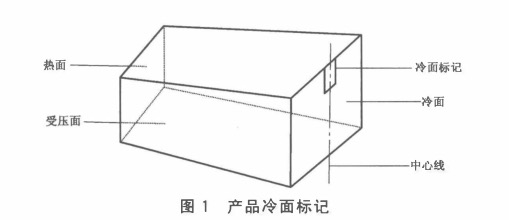

4.4楔形砖的冷面必须有标记,标记采用“沟槽”法。沟槽应位于砖冷面中心线,所有的槽口周边应星弧形,为槽不应贯穿冷面,标记应在受压面的对面的校一方,沟槽尺寸不做规定,如图1所示:

|

表3产品的尺寸允许偏差、外观及断面检查要求 单位:mm |

|||||||

|

项目 |

指 标 |

||||||

|

XRG-96 |

ZBG-96 |

DBG-96 |

|||||

|

尺寸允许偏差 |

尺寸 |

≤100 |

±1 |

±1.5 |

±1.5 |

||

|

>100~≤350 |

±2 |

±2.5 |

±2.5 |

||||

|

>350 |

±3 |

±3.5 |

±3.5 |

||||

|

楔度差 |

2 |

2 |

2 |

||||

|

扭曲 |

长 度 |

≤250 |

≤ |

1 |

1 |

1 |

|

|

>250~≤450 |

≤ |

1.5 |

1.5 |

1.5 |

|||

|

>450 |

≤ |

2 |

2 |

2 |

|||

|

缺棱长度(a+b+c) |

工作面 |

≤ |

21 |

25 |

40 |

||

|

非工作面 |

≤ |

40 |

50 |

60 |

|||

|

缺角深度(d+e+f) |

工作面 |

≤ |

21 |

25 |

40 |

||

|

非工作面 |

≤ |

40 |

50 |

60 |

|||

|

熔洞直径 |

工作面 |

不允许 |

≤5 |

≤5 |

|||

|

非工作面 |

≤ |

5 |

10 |

10 |

|||

|

裂纹长度 |

宽度≤0.1 |

允许 |

允许 |

允许 |

|||

|

宽度0.1~0.25(包括0.25) |

工作面 |

≤ |

30 |

30 |

30 |

||

|

非工作面 |

≤ |

50 |

50 |

50 |

|||

|

宽度0.25~0.5(包括0.5) |

工作面 |

不允许 |

不允许 |

不允许 |

|||

|

非工作面 |

≤ |

30 |

30 |

30 |

|||

|

宽度>0.5 |

不允许 |

不允许 |

不允许 |

||||

|

断面 |

层裂 |

不允许 |

不允许 |

不允许 |

|||

|

注1:制品工作面为直形制品一个端面和一个侧面;楔形制品小端面或侧面;其他制品按图纸规定的面,注2:裂纹只允许跨越过一个校,跨校裂纹不合并计算。 |

|||||||

5试验方法

5.1化学成分按GB/T 6901进行。

5.2体积密度、显气孔率按GB/T 2997-2000进行

5.3真密度按GB/T 5071进行。

5.4常温耐压强度按GB/T 5072进行

5.5重烧线变化率按GB/T 5988进行。

5.6荷重软化温度按YB/T 370-1995进行

5.7热膨胀率按GB/T 7320.1进行。

5.8砖的尺寸允许偏差、外观及断面的检查按GB/T10326-2001进行。

6检验规则

6.1每150吨为一个检验批量,不足150吨时仍按一个批量计

6.2 尺寸和外观检验的抽样方案按表4的规定进行(等同于GB/T 10325-2001)。设样本量(m)中的不合格数为y,若y≤c,整批制品为合格批;若y>c,整批制品为不合格批。

|

表4抽样方案 |

||

|

批量(块数)N |

样本量,n |

接收数,c |

|

51~90 |

5 |

1 |

|

91~150 |

8 |

1 |

|

151~280 |

13 |

2 |

|

281~500 |

20 |

3 |

|

501-1200 |

32 |

5 |

|

1201~3200 |

50 |

7 |

|

>3200 |

80 |

10 |

6.3木标准规定考核的理化性能项目为,化学成分、显气孔率、常温耐压强度、荷重软化温度。也可由供需双方商定。

6.4破坏性检验的样品应从外观检查合格的样本中抽取。测试单值均须符合表2中相应检验项目的规定。如果第一次抽样检验不符合要求,应在该批制品中再随机抽取双倍数量的测试样本,进行该不合格项目的复检,复检结果的平均值若符合要求,其中测试单值均在产品标准规定的偏差或供需双方切商的偏差之内,判为合格批;否则判为不合格批。试样的检验结果允许偏差应符合表5的规定

|

表5产品理化性能的允许偏差 |

|||

|

项目 |

单位 |

允许偏差 |

举 例 |

|

SiO2 |

% |

-0.3 |

优质硅砖的牌号为XBG-96的SiO2≥96%,允许单个SiO2≥95.7%。 |

|

Fe2O3 |

% |

+0.1 |

优质硅砖的牌号为XBG-96的Fe2O3<0.9%,允许单个Fe2O3≤1.0%。 |

|

熔融指数 |

% |

0 |

优质硅砖的牌号为XBG-96的熔融指数≤0.5。 |

|

显气孔率 |

% |

+1 |

优质硅砖的牌号为XBG-96的显气孔率≤22%,允许单个显气孔率≤23%。 |

|

真密度 |

g/cm³ |

+0.01 |

优质硅砖的牌号为XBG-96的真密度≤2.34,允许单个真密度≤ |

|

0.2MPa 荷重软化 |

℃ |

-10 |

优质硅砖的牌号为XBG-96的荷软温度≥1680℃,允许单个荷软温度≥1670℃。 |

|

常温耐压强度 |

MPa |

-5 |

优质硅砖的牌号为XBG-96的常温耐压强度≥40MPa,允许单个耐压强度≥35MPa |

|

重烧线变化(1450℃x2h) |

% |

+0.1 |

优质硅砖的牌号为XBG-96的重烧线变化率≤+0.3%,允许单个重烧线变化率≤+0.4%。 |

7包装、标志、运输、储存和质量证明书

7.1标志、包装、运输、储存应符合 GB/T 16546 的规定。

7.2砖发货时必须附有质量监督部门签发的质量证明书,载明供方名称、需方名称、生产日期、合同号、产品名称、标准编号、牌号、批号、尺寸、外观及理化指标等内容。

High quality silica brick for glass kiln

1 Range

This standard specifies the classification, technical requirements, test methods, inspection rules and marking, packaging, transportation, storage and quality certificate requirements of high-quality silica bricks for glass kilns.

This standard applies to high quality silicon bricks with a single weight of not more than 40kg (hereinafter referred to as the product), which are pressed by the machine for masonry glass inspection.

2 Normative reference documents

The terms in the following documents become terms of this Standard by reference to this Standard. All subsequent amendments (excluding errata) or revisions to dated citations are not applicable to this Standard; however, parties to an agreement under this Standard are encouraged to explore the use of the most recent version of these documents. For undated references, the latest version of the document applies to this standard.

GB/T 29972000 Test method for apparent porosity, water absorption, bulk density and true porosity of dense shaped refractory products.

GB/T 5071 refractories true density test method.

GB/T 5072 compact shaped refractory products test method for compressive strength at room temperature.

GB/T 5988 compact shaped refractory products test method for reburning line change.

YB/T 370-1995 Test method for load softening temperature of refractory products (non-differential rising temperature method).

GB/T 6901 Method for chemical analysis of silica refractories.

GB/T 7320.1 Test method for thermal expansion of refractory products.

GB/T 7321 dense shaped refractory product test sample preparation provisions.

GB/T 10325-2001 Rules for sampling acceptance of shaped refractory products.

GB/T 10326-2001 Method for inspection of size, appearance and section of refractory products.

GB/T 16546-1996 Packaging, marking, transport and storage of shaped refractory products.

YB/T 4017 Glass kiln refractory products Shape size silicon brick.

3 Classification, shape and size

3.1 Classification Products are divided into three brands according to their single weight, as shown in Table 1.

|

Table 1 Product classification |

|

|

Brand |

Single weight,kg |

|

XBG-96 |

≤15 |

|

ZBG-96 |

15.1~25 |

|

DBG-96 |

25.1~40 |

Note 1: X, 2 and D in the brand respectively refer to the initial letters of small, medium and large Chinese pinyin. B and G are the initials of glass kiln and silicon brick in Chinese pinyin.

3.2 The shape and size of the product shall comply with the provisions of YB/T4017

4 Technical Requirements

4.1 The physical and chemical properties of the product shall comply with the provisions of Table 2.

|

Table 2 Physical and chemical properties of the products |

||||||

|

Item |

Unit |

Index |

||||

|

XBG-96 |

ZBG-96 |

DBG-96 |

||||

|

Chemical composition |

SiO2 |

≥ |

% |

96 |

96 |

96 |

|

Fe2O3 |

≤ |

% |

0.8 |

0.8 |

0.8 |

|

|

Melt index(Al2O3)+2RO2) |

≤ |

% |

0.5 |

0.5 |

0.5 |

|

|

Physical property |

Apparent porosity |

≤ |

% |

21 |

21 |

21 |

|

True density |

≤ |

g/cm³ |

2.34 |

2.34 |

2.34 |

|

|

0.2MPa load softening starting temperature |

≥ |

℃ |

1680 |

1680 |

1680 |

|

|

Compressive strength at room temperature |

≥ |

MPa |

35 |

30 |

30 |

|

|

Heavy burn line change(1450℃x2h) |

≤ |

% |

+0.2 |

+0.2 |

+0.2 |

|

|

Thermal expansion rate(0℃~1450℃) |

% |

Provide measured data |

||||

4.2 Product appearance quality, size permissible deviation and section inspection shall comply with the provisions of Table 3

4.3 The technical requirements for handmade bricks and bricks of single weight greater than 40kg shall be agreed upon by both parties.

4.4 The cold side of the wedge-shaped brick must be marked, and the marking shall adopt the “groove” method. Grooves should be located in the center line of the cold surface of the brick, and all the grooves should be curved around the star, so that the grooves should not run through the cold surface, and the marks should be on the opposite side of the pressure surface, and the grooves size is not specified, as shown in Figure1:

|

Table 3: Requirements for inspection of allowable deviations in size, appearance and section of the product Unit:mm |

|||||||

|

Item |

Index |

||||||

|

XRG-96 |

ZBG-96 |

DBG-96 |

|||||

|

Allowable deviation of dimension |

Dimension |

≤100 |

±1 |

±1.5 |

±1.5 |

||

|

>100~≤350 |

±2 |

±2.5 |

±2.5 |

||||

|

>350 |

±3 |

±3.5 |

±3.5 |

||||

|

Wedge difference |

2 |

2 |

2 |

||||

|

Distortion |

Length |

≤250 |

≤ |

1 |

1 |

1 |

|

|

>250~≤450 |

≤ |

1.5 |

1.5 |

1.5 |

|||

|

>450 |

≤ |

2 |

2 |

2 |

|||

|

Missing Angle length(a+b+c) |

Working face |

≤ |

21 |

25 |

40 |

||

|

Non-working face |

≤ |

40 |

50 |

60 |

|||

|

Missing edge length(e+f+g) |

Working face |

≤ |

21 |

25 |

40 |

||

|

Non-working face |

≤ |

40 |

50 |

60 |

|||

|

Hole diameter |

Working face |

Not allow |

≤5 |

≤5 |

|||

|

Non-working face |

≤ |

5 |

10 |

10 |

|||

|

Crack length |

Breadth≤0.1 |

Allow |

Allow |

Allow |

|||

|

Width 0.1~0.25(including 0.25) |

Working face |

≤ |

30 |

30 |

30 |

||

|

Non-working face |

≤ |

50 |

50 |

50 |

|||

|

Width 0.25~0.5(including 0.5) |

Working face |

Not allow |

Not allow |

Not allow |

|||

|

Non-working face |

≤ |

30 |

30 |

30 |

|||

|

Breadth>0.5 |

Not allow |

Not allow |

Not allow |

||||

|

Section |

Slabbing |

Not allow |

Not allow |

Not allow |

|||

|

Note 1: The working face of the product is one end face and one side side of the straight product; A small face or side of a wedge-shaped product; Other products according to the drawing specified surface, note 2: cracks are only allowed to cross one school, cross-school cracks are not combined. |

|||||||

5 Test methods

5.1 Chemical composition according to GB/T 6901.

5.2 Bulk density and apparent porosity are calculated according to GB/T 2997-2000

5.3 The true density is GB/T 5071.

5.4 The compressive strength at room temperature shall be GB/T 5072

5.5 The reburn wire change rate is GB/T 5988.

5.6 The load softening temperature was carried out according to YB/T 370-1995

5.7 The thermal expansion rate is GB/T 7320.1.

5.8 The inspection of allowable deviation, appearance and section of bricks shall be carried out in accordance with GB/T10326-2001.

6 Inspection Rules

6.1 Each 150 tons shall be one inspection lot, and if it is less than 150 tons, it shall be counted as one lot

6.2 The sampling scheme for dimensional and visual inspection shall be carried out as specified in Table 4 (equivalent to GB/T 10325-2001). Set the number of unqualified in sample size (m) as y, if y≤c, the whole batch of products is qualified; If y>c, the whole batch of products is unqualified.

|

Table 4 Sampling scheme |

||

|

Batch (number of blocks)N |

Sample size, n |

Number of receptions, c |

|

51~90 |

5 |

1 |

|

91~150 |

8 |

1 |

|

151~280 |

13 |

2 |

|

281~500 |

20 |

3 |

|

501-1200 |

32 |

5 |

|

1201~3200 |

50 |

7 |

|

>3200 |

80 |

10 |

6.3 The physical and chemical properties of wood are as follows: chemical composition, apparent porosity, compressive strength at room temperature and softening temperature under load. It can also be agreed between the supply and demand parties.

6.4 Samples for destructive testing shall be taken from samples that have passed the inspection. All test values must conform to the requirements of the corresponding test items in Table 2. If the first sampling inspection does not meet the requirements, the batch of products shall be randomly selected to double the number of test samples for the reinspection of the unqualified items. If the average value of the reinspection results meets the requirements, in which the test single value is within the deviation specified in the product standard or the deviation between the supply and demand parties, the batch shall be judged as qualified; Otherwise, it will be judged as unqualified batch. The permissible deviation of the test result of the sample shall comply with the provisions of Table 5.

|

Table 5 Allowable deviations of physical and chemical properties of products |

|||

|

Item |

Unit |

Allowable deviation |

Take an example |

|

SiO2 |

% |

-0.3 |

The grade of high quality silicon brick is SiO2≥96% of XBG-96, allowing a single SiO2≥95.7%. |

|

Fe2O3 |

% |

+0.1 |

The grade of high quality silicon brick is XBG-96 Fe2O3<0.9%, allowing a single Fe2O3≤1.0%. |

|

Melt index |

% |

0 |

The melting index of high quality silicon brick is XBG-96 ≤0.5. |

|

Apparent porosity |

% |

+1 |

The apparent porosity of high quality silicon brick brand XBG-96 is less than 22%, allowing a single apparent porosity ≤23%. |

|

True density |

g/cm³ |

+0.01 |

The true density of high quality silicon brick is XBG-96 ≤2.34, allowing a single true density ≤ 2.35g/cm. |

|

0.2MPa load softening Starting temperature |

℃ |

-10 |

High quality silicon brick brand XBG-96 load soft temperature ≥1680℃, allowing a single load soft temperature ≥1670℃。 |

|

Compressive strength at room temperature |

MPa |

-5 |

The grade of high quality silicon brick is XBG-96, which has a normal temperature compressive strength ≥40MPa, and allows a single compressive strength ≥35MPa |

|

Reburn line change (1450℃x2h) |

% |

+0.1 |

The reburning line change rate of high quality silicon brick brand XBG-96 is ≤+0.3%, allowing a single reburning line change rate ≤+0.4%. |

7 Packing, marking, transportation, storage and quality certificate

7.1 Marking, packaging, transportation and storage shall comply with the provisions of GB/T 16546.

7.2 The bricks must be delivered with a quality certificate issued by the quality supervision department, indicating the name of the supplier, the name of the buyer, the date of production, the contract number, the name of the product, the standard number, the grade number, the batch number, the size, the appearance and the physical and chemical index.