JC/350-1993 水泥窑用磷酸盐结合高铝质砖/Phosphate-bonded high alumina bricks for cement kilns

水泥窑用磷酸盐结合高铝质砖

1主题内容与适用范围

本标准规定了水泥窑用磷酸盐结合高铝质砖的产品分类、技术要求、试验方法、检验规则、标志、包装、运输、贮存及质量证明书等。

本标准适用于用作水泥回转窑的过渡带、烧成带、冷却带、冷却机及机立窑的工作层等部位的确酸盐结合高铝质砖的生产和检验。

2引用标准

GB 2997致密定形耐火制品显气孔率、吸水率、体积密度和真气孔率试验方法

GB 5072致您定形耐火制品常温耐压强度试验方法

GB 5989致密定形耐火制品荷重软化温度试验方法(示差升温法)

GB 6900粘土、高铝质耐火材料化学分析方法

GB 7322耐火材料耐火度试验方法

GB 10325耐火制品堆放、取样、验收、保管和运输规则

GB 10326耐火制品尺寸、外观及断面的检查方法

3术语

磷酸盐结合高铝质砖:以高铝矶土熟料为骨料和细粉,磷酸或磷酸铝为结合剂,经半干法压制成型400~600C热处理的化学结合而成的高铝质耐火制品。

4分类、等级、形状和尺寸

4.1制品按结合剂分为两个品种

a.磷酸盐结合高铝质砖(简称磷酸盐砖)结合剂为浓度 42.5%~50%磷酸溶液。代号为P,锁缝砖代号为PC。

b.磷酸铝结合高铝质耐磨砖(简称耐磨砖)结合剂为工业磷酸、工业氢氧化铝配成的磷酸铝溶液摩尔比为Al2O3、P2O5=1:3.2。代号为PA。

4.2等级

按理化指标、尺寸和外观分为一等品、合格品。

4.3形状和尺寸

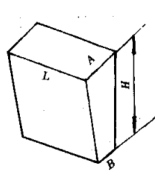

4.3.1用于回转窑窑内的磷酸盐砖的形状、尺寸应符合表1的规定

|

表1 mm |

|||||||||

|

砖型 |

砖号 |

适用窑内径(m) |

尺寸 |

每砌一圈用砖数块 |

每砌一米用砖数块 |

||||

|

L |

H |

A |

B |

(A-B) |

|||||

|

|

PC12 PC16 PC20 PC25 PC30 PC33 PC36 PC40 PC3 PC46

|

1.1~1.5 |

198 198 198 198 198 198 198 198 198 198 |

100 120 150 150 180 180 180 200 200 200 |

71 80 81 90 92 83 100 90 97 92 |

60 69 70 80 81 74 90 81 88 84 |

11 11 11 10 11 9 8 |

49~67 73~87 78~94 88~101 103~110 125~133 113~123 140~147 139~146 157~164 |

244~334 365~435 390~470 440~505 515~550 625~665 565~615 700~735 695~730 785~820 |

注:砖号下标数表示窑内径尺寸

4.3.2.回转窑内锁缝用磷酸盐砖的形状尺寸应符合表2的规定。

|

表2 mm |

||||||||||

|

砖型

|

砖号

|

适用窑内径(m)

|

尺 寸 |

每砌一圈用砖数块

|

每砌一米用砖数块

|

|||||

|

L |

H |

A |

B |

(A-B) |

||||||

|

|

PC1-1 PC1-2 PC1-3 |

1.1~1.5 |

198 198 198 |

100 100 100 |

90 60 50 |

79 49 39 |

11 11 11 |

2 2 2 |

10 10 10 |

|

|

PC1-4 PC1-5 PC1-6 |

1.6~1.9 |

198 198 198 |

120 120 120 |

90 60 50 |

79 49 39 |

11 11 11 |

2 2 2 |

10 10 10 |

||

|

PC2-1 PC2-2 PC2-3 |

2.0~2.9 |

198 198 198 |

150 150 150 |

100 70 60 |

90 60 50 |

10 10 10 |

2 2 2 |

10 10 10 |

||

|

PC3-1 PC3-2 PC3-3 |

3.0~3.9 |

198 198 198 |

180 180 180 |

110 70 60 |

101 61 51 |

9 9 9 |

2 2 2 |

10 10 10 |

||

|

PC4-1 PC4-2 PC4-3 |

4.0~4.9 |

198 198 198 |

200 200 200 |

100 70 60 |

91 61 51 |

9 9 9 |

2 2 2 |

10 10 10 |

||

4.3 3耐磨砖的形状、尺寸由供需双方商定。

|

表3 |

|||||

| 项目 |

指标 |

||||

|

P |

PA |

||||

|

一等品 |

合格品 |

一等品 |

合格品 |

||

|

化 学 成 分

|

Al2O3,% 不小于 |

75 |

77 |

||

|

Fe2O3,% 不大于 |

3.2 |

3.2 |

|||

|

CaO,% 不大于 |

0.6 |

0.6 |

|||

|

常温耐压强度,MPa 不小于 |

70 |

60 |

75 |

65 |

|

|

体积密度,kg/m 不小于 |

2700 |

2650 |

2750 |

2700 |

|

|

荷重软化温度T0.6℃ 不小于 |

1350 |

1300 |

1300 |

1250 |

|

|

耐火度,℃ 不小于 |

1780 |

||||

5.2制品的尺寸允许偏差和外观质量应符合表4的规定。

|

表4 mm |

||

|

项目 |

数 值 |

|

|

一等品 |

合格品 |

|

|

尺寸允许偏差:

|

±1 ±2 |

±1.5 ±2 ±2.5 |

|

由供需双方商定 |

||

|

扭曲:

|

1.5 |

2.0 |

|

由供需双方商定 |

||

|

缺角: |

10 1个 |

10 1 个 |

|

缺棱: 长度 不大于 |

5 |

7 |

|

裂纹: |

不限制 25 不允许 |

不限制 50 不允许 不允许 |

5.3异型制品的技术要求由供需双方商定。

6试验方法

6.1制品的化学分析按GB 6900的规定进行试验。

6.2制品的常温耐压强度按GB 5072的规定进行测定。

6.3制品的体积密度按GB 2997的规定进行测定。

6.4制品的荷重软化温度按GB 5989的规定进行测定。

6.5制品的耐火度按GB 7322的规定进行测定。

6.6制品的尺寸、外观按GB 10326的规定进行检查。

7检验规则

7.1检验项目

7.1.1出厂检验

出厂检验项目包括制品的尺寸、外观、体积密度、耐压强度、荷重软化温度和三氧化二铝含量。

7.1.2型式检验

型式检验项目包括本标准第5章规定的全部技术要求。在下列情况下对制品进行型式检验。

a)正常生产时,半年或一年进行一次检验;

b)产品长期停产后,恢复生产时;

c)出,检验结果与上次型式检验有较大差异时;

d)当原料发生变动时;

e)国家质量监督机构提出进行型式检验的要求时。

7.2取样规则,检验结果的判定,复验规定等按 GB 10325 的规定进行,取样批量同GB 10325中的高铝砖。当制品的理化性能指标、尺寸允许偏差及外观均满足一等品时,则为一等品。

8标志、包装、运输、贮存

8.1标志

8.1.1每块产品的显著位置必须有不易擦掉的标志、生产厂名或商标,以及产品的牌号和质量等级。

8.1.2制品的使用热面应有明显的热面使用标记,以便识别。

8.2包装

制品应买为包装,以保证运输过程中不易破损,外形完整。

8.3运输、贮存应按GB 10325的规定进行。

8.4质量证明书

每批产品发出时必须附有供方质量监督部门签发的质量证明书,其中要求注明:

a)供方名称;

b)需方名称;

c)发货日期;

d)产品种类、数量;

e)检验报告、产品等级;

f)合同号。

Phosphate-bonded high alumina bricks for cement kilns

1Subject content and scope of application

This standard specifies the product classification, technical requirements, test methods, inspection rules, marking, packaging, transportation, storage and quality certificate of phosphate bonded high alumina bricks used in cement kilns.

This standard is applicable to the production and inspection of high aluminum-bonded bricks used in transition zones, firing zones, cooling zones, coolers and working layers of mechanical shaft kilns.

2 Reference Standards

GB 2997 Test method for apparent porosity, water absorption, bulk density and true porosity of compact shaped refractory products

GB 5072 shaped refractory products test method for compressive strength at room temperature

GB 5989 Test method for load softening temperature of compact shaped refractory products (differential rising temperature method)

GB 6900 Methods for chemical analysis of clay and high alumina refractories

GB 7322 refractoriness test method

GB 10325 Rules for stacking, sampling, acceptance, storage and transportation of refractory products

GB 10326 refractory products size, appearance and section inspection method

3 Terms

Phosphate bonded high alumina brick: high alumina rock clinker as aggregate and fine powder, phosphoric acid or aluminum phosphate as bonding agent, by semi-dry pressing forming 400~600C heat treatment of chemical combination of high alumina refractory products.

4 Classification, grade, shape and size

4.1 Products are divided into two varieties according to the binder

a.Phosphate-bonded high aluminum brick (referred to as phosphate brick) binder is a concentration of 42.5%~50% phosphoric acid solution. Code P, lock brick code PC.

b.Aluminum phosphate combined with high aluminum wear-resistant brick (referred to as wear-resistant brick) bond for industrial phosphoric acid, industrial aluminum hydroxide prepared by aluminum phosphate solution molar ratio of Al2O3, P2O5=1:3.2. Code name PA.

4.2 level

According to physical and chemical indicators, size and appearance are divided into first-class products, qualified products

4.3 Shape and dimensions

4.3.1 The shape and size of phosphate bricks used in rotary kilns shall comply with the provisions of Table 1.

|

Table 1 mm |

|||||||||

|

Brick shape |

Brick number |

Applicable kiln inner diameter (m) |

Dimension |

Use several bricks per circle |

Use several bricks per meter |

||||

|

L |

H |

A |

B |

(A-B) |

|||||

|

|

PC12 PC16 PC20 PC25 PC30 PC33 PC36 PC40 PC3 PC46

|

1.1~1.5 |

198 198 198 198 198 198 198 198 198 198 |

100 120 150 150 180 180 180 200 200 200 |

71 80 81 90 92 83 100 90 97 92 |

60 69 70 80 81 74 90 81 88 84 |

11 11 11 10 11 9 8 |

49~67 73~87 78~94 88~101 103~110 125~133 113~123 140~147 139~146 157~164 |

244~334 365~435 390~470 440~505 515~550625~665 565~615 700~735 695~730 785~820 |

Note: The brick number subscript indicates the inner diameter of the kiln

4.3.2. The shape and size of phosphate bricks for locking joint in rotary kiln shall comply with the provisions of Table 2.

|

表2 mm |

||||||||||||

|

Brick number |

Applicable kiln inner diameter (m) |

Applicable kiln inner diameter (m)) |

Brick shape |

Brick number |

Applicable kiln inner diameter (m) |

Dimension |

Use several bricks per circle |

Use several bricks per meter |

||||

|

L |

H |

A |

B |

(A-B) |

||||||||

|

|

PC1-1 PC1-2 PC1-3 |

1.1~1.5 |

198 198 198 |

100 100 100 |

90 60 50 |

79 49 39 |

11 11 11 |

2 2 2 |

10 10 10 |

|||

|

PC1-4 PC1-5 PC1-6 |

1.6~1.9 |

198 198 198 |

120 120 120 |

90 60 50 |

79 49 39 |

11 11 11 |

2 2 2 |

10 10 10 |

||||

|

PC2-1 PC2-2 PC2-3 |

2.0~2.9 |

198 198 198 |

150 150 150 |

100 70 60 |

90 60 50 |

10 10 10 |

2 2 2 |

10 10 10 |

||||

|

PC3-1 PC3-2 PC3-3 |

3.0~3.9 |

198 198 198 |

180 180 180 |

110 70 60 |

101 61 51 |

9 9 9 |

2 2 2 |

10 10 10 |

||||

|

PC4-1 PC4-2 PC4-3 |

4.0~4.9 |

198 198 198 |

200 200 200 |

100 70 60 |

91 61 51 |

9 9 9 |

2 2 2 |

10 10 10 |

||||

4.3.3 The shape and size of wear-resistant bricks shall be agreed upon by both parties.

|

Table 3 |

|||||

|

Item

|

Index |

||||

|

P |

PA |

||||

|

First grade goods |

Qualified product |

First grade goods |

Qualified product |

||

|

Chemical composition

|

Al2O3,% No less than |

75 |

77 |

||

|

Fe2O3,% Not more than |

3.2 |

3.2 |

|||

|

CaO,% Not more than于 |

0.6 |

0.6 |

|||

|

Compressive strength at room temperature,MPa No less than |

70 |

60 |

75 |

65 |

|

|

Bulk density,kg/m No less than |

2700 |

2650 |

2750 |

2700 |

|

|

Softening temperature under loadT0.6℃ No less than |

1350 |

1300 |

1300 |

1250 |

|

|

Refractoriness,℃ No less than |

1780 |

||||

5.2 The permissible size deviation and appearance quality of the product shall comply with the provisions of Table 4.

|

Table 4 mm |

||

|

Item

|

Index |

|

|

First grade goods |

Qualified product |

|

|

Allowable deviation of dimension:

|

±1 ±2 |

±1.5 ±2 ±2.5 |

|

To be agreed upon by supply and demand |

||

|

Contort:

|

1.5 |

2.0 |

|

To be agreed upon by supply and demand |

||

|

Missing corner: |

10 1 |

10 1 |

|

Wane: Length Not more than |

5 This edge is 1/4 long 2 pieces |

7 This edge is 1/4 long 2 pieces |

|

Crack: Width ≤0.25 Width 0.26~0.50 Length Not more than Width >0.50 A crack across two or more edges |

No limit 25 Not allow Not allow |

No limit 50 Not allow Not allow |

5.3 The technical requirements of shaped products shall be agreed by both parties.

6 Test methods

6.1 Chemical analysis of the product shall be carried out in accordance with GB 6900.

6.2 The compressive strength of the product at room temperature shall be determined according to the provisions of GB 5072.

6.3 The bulk density of the product shall be determined according to the provisions of GB 2997.

6.4 The load softening temperature of the product shall be determined according to the provisions of GB 5989.

6.5 The refractories of the products shall be determined according to the provisions of GB 7322.

6.6 The size and appearance of the product shall be checked according to the provisions of GB 10326.

7 Inspection Rules

7.1 Inspection Items

7.1.1 Factory inspection

The factory inspection items include the size, appearance, bulk density, compressive strength, load softening temperature and aluminum oxide content of the product.

7.1.2 Type inspection

The type inspection item includes all the technical requirements specified in Chapter 5 of this standard. Type inspection of articles is carried out in the following cases.

a) During normal production, inspection should be carried out half a year or once a year;

b) When the production of the product is resumed after a long period of suspension;

c) when the test results are significantly different from the last type test;

d)When there is a change in raw materials;

e) When the national quality supervision authority makes a request for type inspection.

7.2 Sampling rules, determination of inspection results, reinspection regulations, etc. shall be carried out in accordance with the provisions of GB 10325, and the sampling batch shall be the same as that of high aluminum bricks in GB 10325. When the physical and chemical properties of the product, the allowable deviation of size and the appearance of the product meet the first class, it is a first class product.

8.Marking, packaging, transportation and storage

8.1 Flags

8.1.1 The prominent position of each product must be marked with the indelible logo, the name of the manufacturer or trademark, as well as the brand and quality grade of the product.

8.1.2 The use of the hot surface of the product should have a clear hot surface use mark for identification.

8.2 Packaging

The product should be bought in packaging to ensure that it is not easily damaged during transportation and the shape is complete.

8.3 Transportation and storage shall be carried out in accordance with GB 10325.

8.4 Certificate of Quality

Each batch of products must be accompanied by a quality certificate issued by the quality supervision department of the supplier, which requires that:

a) Name of the supplier;

b) Demander’s name;

c) Delivery date;

d) Product type and quantity;

e) Inspection report, product grade;

f) Contract number.