钢包用耐火材料的使用条件和构筑工艺

铸锭用耐火材料一、钢包钢包是耐火材料的一大用户。钢包耐火材料受下列破坏因素的影响。(一)使用条件(1)在1530~1700℃的温度下,受到钢水和渣的热和化学作用。(2)钢包装满以及卸空时,被急剧的加热和冷却,温差为800~1350℃。(3)装入时,受到一般熔化的金属和渣流的机械冲击和磨损作用。(4)钢水和渣的流体动力学作用。

钢包衬损坏决定于灌进钢水时期,钢包内钢水进入时间和数量,渣成分和渣层厚度。一般灌进钢水时期钢水在包内停留30~150min之间波动,而渣层厚度达到300mm。

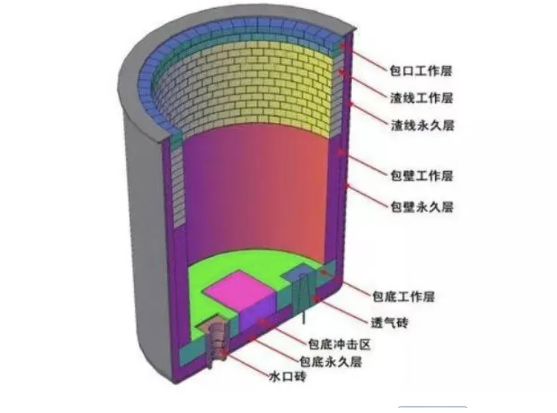

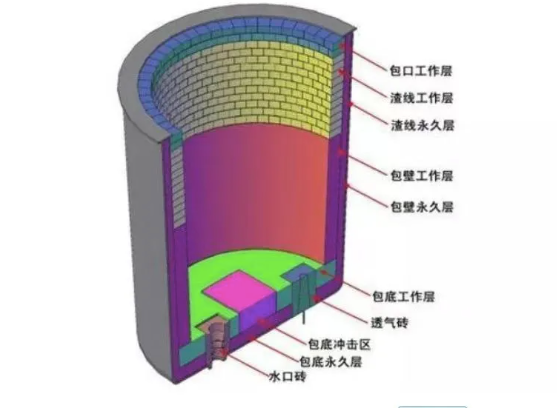

(二)内衬构筑方法及耐火材料

像砌筑小块制品(钢包砖)的钢包一样,用各种成分的浇注料整体浇注。钢包砌砖实行螺旋状和阶梯形砌筑(图11-8)。300t钢包下部砌体厚度200mm,而上部90mm❶。过去钢包砖通常用黏土砖砌筑,砖的寿命主要取决于使用条件。钢包砖的单位消耗,在浇注平炉和转炉钢时约为 6kg/t,而电炉钢约为 11kg/t,说明内衬寿命与浇的钢类型有关系。

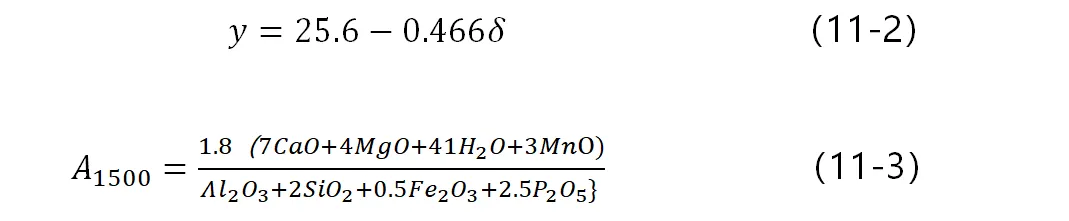

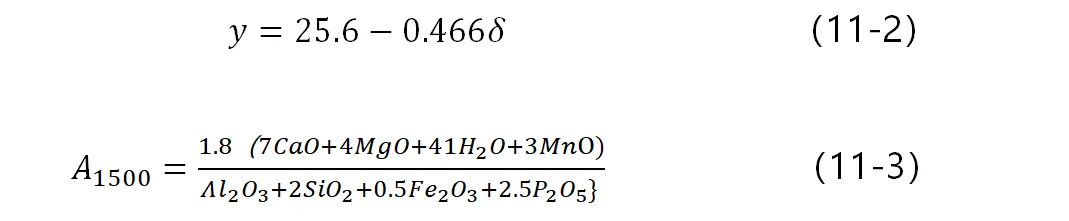

❶ 砌体厚度是不能随意增大的,因为包的重心位置与耐火材料内衬厚度有关系。统计确定钢包砖内衬寿命和侵蚀厚度,与钢包中渣量和它的化学成分有下列关系:

式中,y为内衬寿命(包数);δ为渣层厚度, mm;A1500为 1500℃下侵蚀厚度, mm。在一定条件下得出的公式,而其他条件下的内衬侵蚀,只能说明品质的特性。

Service conditions and construction technology of refractory materials for ladle

Refractory materials for ingot casting 1. Ladle Ladle is a large user of refractory materials. Ladle refractories are affected by the following failure factors. (1) At the temperature of 1530~1700℃, it is subjected to the thermal and chemical action of molten steel and slag. (2) When ladle is filled and unloaded, it is heated and cooled sharply, and the temperature difference is 800~1350℃. (3) When loaded, it is subjected to the mechanical impact and wear of the general molten metal and slag flow. (4) Hydrodynamic action of molten steel and slag.

The damage of ladle lining depends on the time and quantity of ladle entering, slag composition and thickness of slag layer. Generally, the molten steel stays in the ladle for 30-150min and fluctuates, while the thickness of the slag layer reaches 300mm.

(2) lining construction method and refractory materials

Like the ladle for laying small pieces (ladle bricks), it is poured in one piece with various components of castable. The ladle brick is laid in spiral and step shape (Figure 11-8). The thickness of the lower part of the 300t ladle is 200mm, while the upper part is 90mm. In the past, ladle bricks were usually made of clay bricks, and the life of the bricks mainly depended on the conditions of use. The unit consumption of ladle bricks is about 6kg/t when pouring open hearth and converter steel, and about 11kg/t for electric furnace steel, indicating that the lining life is related to the type of steel poured.

The thickness of the masonry should not be increased arbitrarily, because the core position of the bale is related to the thickness of the refractory lining. Statistical determination of ladle brick lining life and erosion thickness, and the amount of slag in ladle and its chemical composition have the following relationship:

Where, y is the lining life (number of packets); δ is the thickness of slag layer, mm; A1500is the erosion thickness at 1500℃ (mm). The formula obtained under certain conditions, and the erosion of the lining under other conditions, can only explain the characteristics of the quality.